Supply for All Applications Lithium is generally extracted from brine or hard rock (spodumene). Brine lithium recovery involves drilling and pumping liquids from underground salar brine to evaporation ponds. Hard rock lithium recovery consists of extracting lithium from the ore.

Our major sourcing of lithium ore is from African countries (DRC, Tanzania, Rwanda, Madagascar etc), Chili and Australia etc. Refined lithium carbonate is then purified into battery precursors used by cathode active material and electrolyte manufacturers. While both lithium carbonate and lithium hydroxide are used in LIB cell manufacturing, the former has been used predominantly because of the higher cost of producing lithium hydroxide.

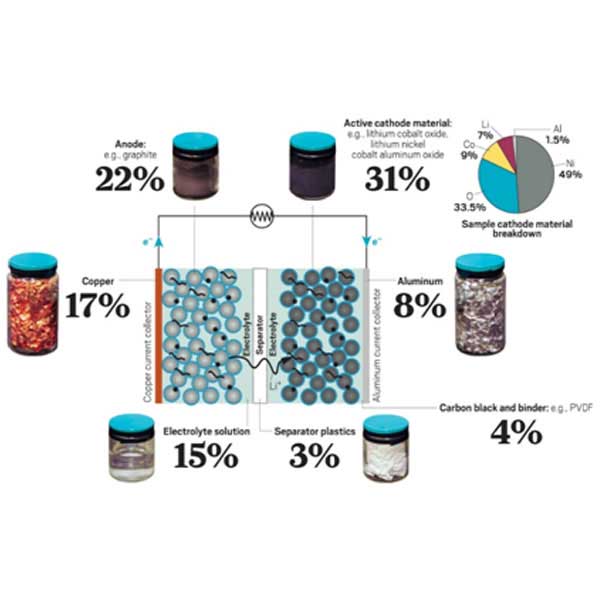

Cobalt is an important ingredient in lithium-ion battery cathode production, accounting for about a quarter of the cost of the battery. The main cobalt supply chain encompasses mining, ore processing to produce concentrates, and refining (through metal and chemical refineries).2 Battery-grade chemicals (battery precursors) from chemical refineries are then used by cathode active material manufacturers. Cobalt is generally mined as a byproduct of either copper or nickel. 67% of cobalt mined was a byproduct of copper, and 32% was a byproduct of nickel, whereas only 1% was produced from primary cobalt mines. Most cobalt deposits are in the Central African Copper belt, which includes countries such as the DRC, the Central African Republic, and Zambia.

Nickel is the most important metal by mass in the lithium-ion battery cathodes used by EV manufacturers. Currently nickel makes up one-third of Nickel Manganese Cobalt (NMC) cathodes and 80% of a Nickel Cobalt Aluminum (NCA) cathodes.

The use of nickel in lithium-ion batteries lends a higher energy density and more storage capacity to batteries. This improved energy density and storage capacity means that electric vehicles can get more miles out of a single charge, a concept that has been a key challenge for widespread EV adoption.

The manganese plays an important role in battery powered products. It acts as a stabilizer in the structure of NMC (nickel manganese cobalt) cathode materials and cathode materials are the key performing drivers of Li-ion batteries.

High-temperature stability distinguishes lithium manganese oxide batteries from others, which are also safer than other lithium-ion battery types

Graphite is the most commonly used to serve as the anode material in lithium-ion battery manufacturing due to its relatively low-cost and its energy density. Graphite has great conductive properties and for the most part is readily available. The Graphite deposits are found in various places on the earth, including Asia, Africa, and North America. However, graphite is not suitable for batteries straight out of the ground and must be processed first.